The Auto Shop Owner’s Guide to Conquering Fall

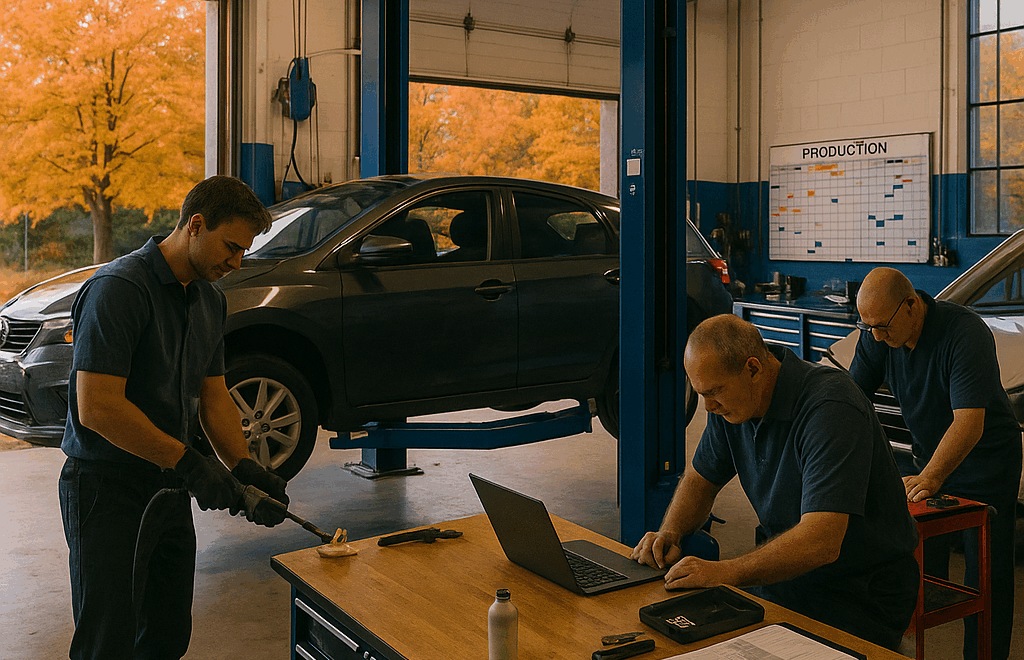

Fall is a make-or-break season for auto repair shops. It’s when a sudden surge of customers, all looking for pre-winter service, can either lead to your most profitable quarter or total chaos.

The key to success isn’t luck; it’s a solid, strategic plan.

This guide, created by people who’ve run their own shops, is a practical blueprint for turning the autumn rush into a streamlined, profitable season.

1. Forecast Demand with Your Own Data

Stop guessing how busy you’ll be. The first step to a smooth fall season is understanding what’s coming.

-

Review past sales: Look at your data from the last two or three years. What services spiked in September and October? (e.g., brake jobs, battery replacements, or tire changes?).

-

Spot the patterns: We’ve found that the busiest time is often from mid-September to early November.

-

Use shop software: A good shop management system can pull up dashboards to help you forecast demand so you know which parts and labor hours to prepare for.

2. Build a Seasonal Parts and Inventory Strategy

A missing part during peak season can cost hours and revenue. Avoid bottlenecks by planning your inventory ahead of time.

Essentials to stock early:

-

Batteries, brake pads, rotors, and calipers.

-

HVAC parts, belts, hoses, and coolant.

-

Winter tires and mounting supplies.

Strategies that work:

-

Increase high-demand stock by 15-25%

-

Bundle parts into “Fall Safety Kits” for fast service

-

Negotiate bulk discounts and rush delivery with suppliers

3. Keep the Bays Moving: Equipment and Layout Prep

Downtime during fall is more expensive than any other season.

Checklist:

-

Inspect lifts, hydraulics, and safety locks

-

Calibrate alignment machines and sensors

-

Pressure-test air compressor systems

-

Replace worn tools before they fail

Layout Tip: Dedicate one bay for “quick jobs” like inspections and wipers. This frees your main bays for higher-ticket repairs.

A Michigan shop cut wait times by 30% in October just by adding a quick-service bay.

4. Get Your Team Ready for Seasonal Workloads

Your staff is the biggest factor in customer satisfaction.

Service advisors:

-

Train to recommend bundled fall services instead of one-offs

-

Manage customer expectations with accurate timelines

-

Streamline scheduling for efficiency

Technicians:

-

Cross-train in HVAC, brakes, and tires to boost flexibility

-

Refresh procedures for seasonal service packages

-

Share workload templates to avoid overtime burnout

Staffing approach:

-

Plan staggered shifts during peak weeks

-

Consider extending hours temporarily

5. Reach Customers Before They Reach You

The busiest shops don’t wait for customers — they invite them in early.

Proactive campaigns:

-

Email segmentation:

-

Loyal customers: thank-you discounts on safety checks

-

Inactive customers: reminders about overdue service

-

-

Educational content: Share weekly fall safety tips on Facebook or LinkedIn

-

Bundled promos: Example: Oil + Brake Check + Wipers = “Fall Readiness Package”

Enhance the experience:

-

Send digital inspection reports with photos

-

Communicate delays proactively

-

Ask for reviews that highlight your fall readiness

6. Track Metrics and Adjust Weekly

Fall success is ongoing, not set-and-forget.

Key metrics to monitor:

-

Bay utilization

-

Average repair order (ARO) value

-

Wait times and customer satisfaction scores

-

Staff overtime hours

-

Inventory turnover and stockout incidents

Best practice: Hold a 15-minute weekly review to spot bottlenecks and adjust.

Shops that run weekly reviews reduce overtime hours by 20% while improving throughput.

7. Proof in Practice: A Real Shop Example

Smith Auto in Ohio prepared by:

-

Stocking 30 extra batteries

-

Dedicating one quick-service bay

-

Launching a “Fall Safety Kit” promo email campaign

Results:

-

40% higher October revenue

-

25% more 5-star Google reviews

-

Staff stress reported as “the lowest fall in years”

8. Final Checklist: What to Do Before the First Cold Front

-

Pull 3 years of service history

-

Place bulk inventory orders by Sept. 15

-

Inspect lifts, calibrate equipment by Oct. 1

-

Train advisors and techs on seasonal packages

-

Launch segmented email + social campaigns by Sept. 20

-

Run weekly performance reviews through fall

Closing: A Smarter Way to Handle Fall

Fall doesn’t have to be chaos. With forecasting, smart stocking, equipment prep, and proactive customer outreach, your shop can transform the busiest season into its most profitable.

Helios was built by shop owners for shop owners. Our real-time dashboards, planning boards, and workflow automation give you the visibility to stay ahead, not just react.

📌 Next Step: Schedule a 15-minute walkthrough of Helios to see how it simplifies fall prep.

Frequently Asked Questions About Fall Auto Shop Prep

1. Why is fall the busiest season for auto repair shops?

Fall brings a surge of customers preparing vehicles for winter. Brakes, batteries, HVAC systems, and tires are all in higher demand, which creates peak workloads for shops.

2. How can auto repair shops prepare for fall demand?

Start by reviewing 2–3 years of service history to forecast which jobs spike in September and October. Then stock seasonal parts, inspect equipment, cross-train staff, and launch early marketing campaigns.

3. What parts should auto shops stock for fall?

The most common items include batteries, brake components, HVAC parts, belts, hoses, coolant, and winter tires. Stocking 15–25% more of these items prevents costly delays.

4. How can shops improve efficiency during fall?

Dedicate a quick-service bay for inspections and light jobs, use a digital production board for visibility, cross-train techs, and run weekly performance reviews to catch bottlenecks.

5. What marketing strategies work best for fall?

Segmented email campaigns, educational social posts, bundled promotions, and early booking incentives work best. Proactive outreach spreads demand and builds trust.